How To Build A Floating Dock With Styrofoam

Purchase or find four 30 gallon plastic drums for your diy floating deck project.

How to build a floating dock with styrofoam. The floats can be installed below the joists or can be placed in between the joists. Build your own floating dock. Is one better for the environment. You will need to run a few beads of silicon caulk to the barrel plugs to make sure to keep the water from filling them.

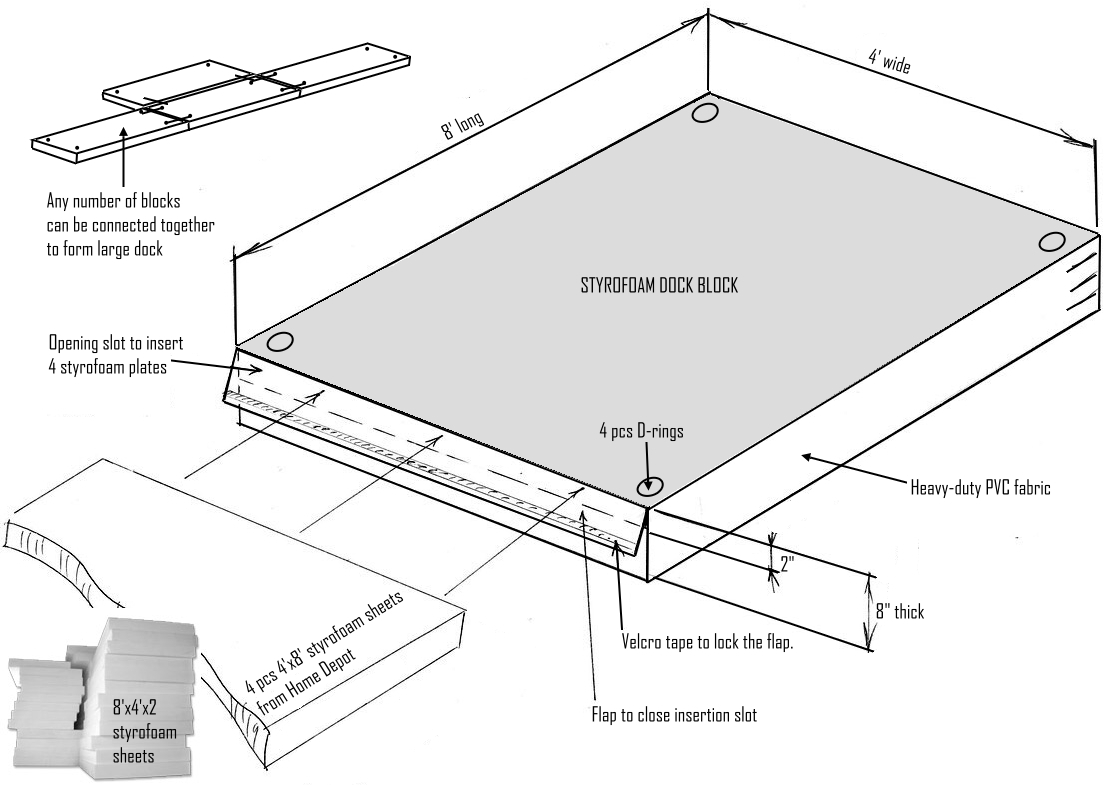

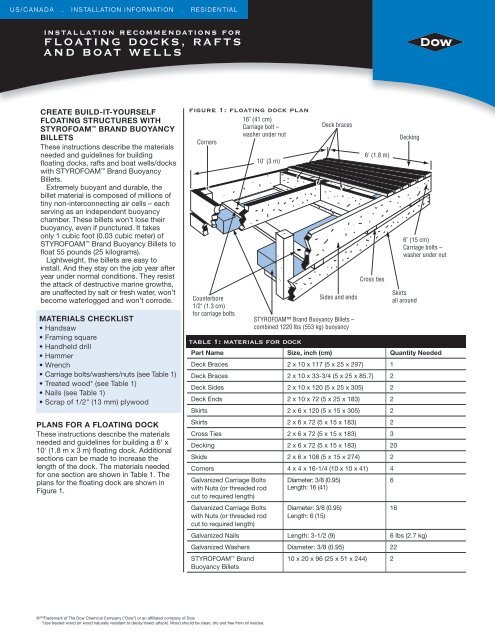

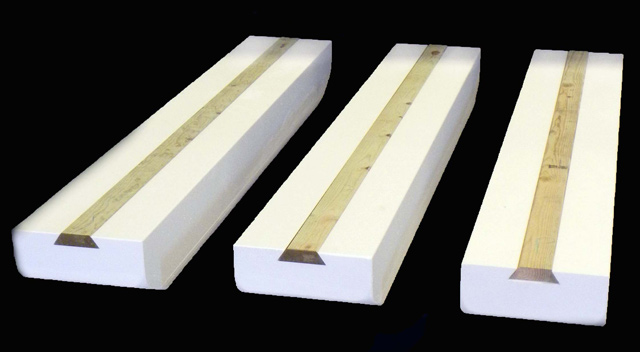

Floating dock foam billets about photos mtgimage build a swim platform plans materials marine floatation eps styrofoam blocks sheets panels permafloat 24 in x 48 12. The remaining bottom layer pieces are playing two roles. Universal foam products has provided both encapsulated floats and un encapsulated floats for hundreds of docks and swim platforms throughout the united states and. Use the formula 1 liter of water occupied by the weight of the dock takes care of 1 kg of dock weight.

Build your deck frame. Measure out the middle of the square and place a 2x4 support there. It is best to use treated wood. Attaching inside dock hardware and.

They are supporting the frame as well as holding the barrels against the dock and preventing them from pushing up against the decking. Using chop saw or skill. Lets say your dock weighs 2000 kg. This will be the weight of the displaced water the styrofoam will occupy.

Its actually quite easy. Calculate the weight of the dock. Placing dock floats on frame for wood floating dock. Cut lumber and build frame for wood floating dock.

To resolve this labour issue for dockworkers lets start from the beginning. Each drum should provide around 250 lbs of flotation. Buoyant foam billets are either expanded polystyrene epsthe white granular material frequently used for beer coolersor closed cell extruded polystyrene foam. Assembly all necessary tools and materials required.

The two most common methods of constructing floating docks use either empty 55 gallon metal storage barrels or large sections of styrofoam. Styrofoam is more versatile and therefore the preferred choice for building custom dock floats. Place two of the boards as the picture shows and lay a barrel on top. Depending upon the size it can be framed using pressure treated lumber ranging from 2x4s to 2x10s spaced 16 on center to over 24 on center.

w~~/s-l1600.jpg)

DocksDebris.jpg)